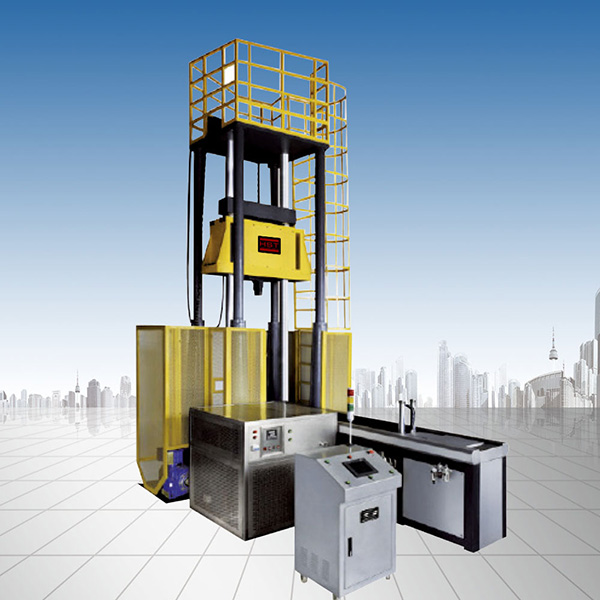

分析液壓萬能試驗機的油缸速度達不到規定值原因

發布時間:2018-11-23 來源:濟南恒思盛大儀器有限公司 瀏覽:次

相信大家都知道液壓萬能試驗機是采用液壓加荷,液壓系統會出現油缸工作速度達不到規定值的情況,那么是什么原因造成的呢,濟南試驗機行家與大家分享,原因大致有八條。

I believe we all know hydraulic universal testing machine is using the hydraulic loading,hydraulic system will appear cylinder operating speed is not up to the specified value, so what is the cause of it, Ji'nan test machine experts to share with you, there are eight reasons.

一、活塞、活塞桿與缸蓋之間同軸度差。

A, piston, piston rod and cylinder coaxial degree difference.

二、液壓萬能試驗機使用不當,外載比預定值大。

Improper use of two, hydraulic universal testing machine, the load is greater than a predetermined value.

三、液壓缸與工作臺平行度差。

Three, the hydraulic cylinder and the table parallel to the poor.

四、內泄漏嚴重。

In four, the serious leakage.

五、密封件破損。

Five, the seal is broken.

六、活塞桿與導向套配合間隙小

Six, the piston rod and the guide sleeve with the gap is small

七、活塞移動時“別勁”,機械裝配質量差。

Seven, the piston moves "don't mind", the poor quality of mechanical assembly.

八、有臟物進入液壓萬能試驗機液壓系統的滑動部位。

Eight, a sliding parts dirt into the hydraulic system of hydraulic universal testing machine.

http://ssnac.com/

- 上一篇:如何調整液壓萬能試驗機的級別

- 下一篇:液壓萬能試驗機應用